From idea to finished product

A short introduction to the world of industrial design

A product doesn’t just happen. Behind every successful design lies a well-thought and structured process in which analysis, creativity, engineering, and manufacturability come together. At Helder Industrial Design, we guide our clients step by step from the initial idea to a manufacturable and fully functional final product. Along the way, we combine strategic insight with hands-on design and technical expertise.

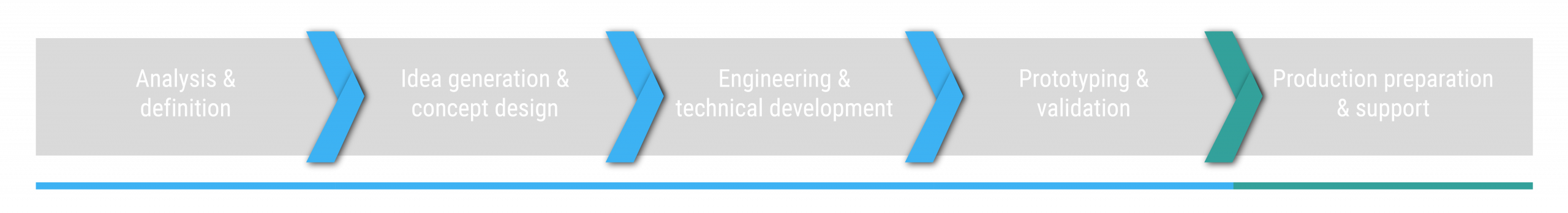

The design process in phases

Our design process consists of the following phases that naturally build upon one another. The exact number of phases and the exact content depend on the product and client’s requirements.

- Analysis & definition

- Idea generation & concept design

- Engineering & technical development

- Prototyping & validation

- Production preparation & support

1. Analysis & definition

In this initial phase, we clearly define the use case and design requirements. What problem are we solving? Who is the user? In what context will the product be used? What requirements must the product meet?

Through discussions, user research and market analysis, we define a clear problem definition, requirements and objectives. Where possible, budgets and production requirements are also incorporated. If these aspects have not yet been defined prior to the project, this phase forms the foundation for the next ones.

2. Idea generation & concept design

Based on the input from the client and/or insights from the previous phase, we begin exploring potential solutions. Using mood boards, sketches, 3D models (both digital and physical) and renderings, we visualize ideas and explore form, functionality and user interaction.

In this phase, multiple concepts are often developed and compared. Together with the client, we determine which concept best fits the objectives, technical feasibility, and desired appearance. In some cases, elements from different concepts are combined into a final direction.

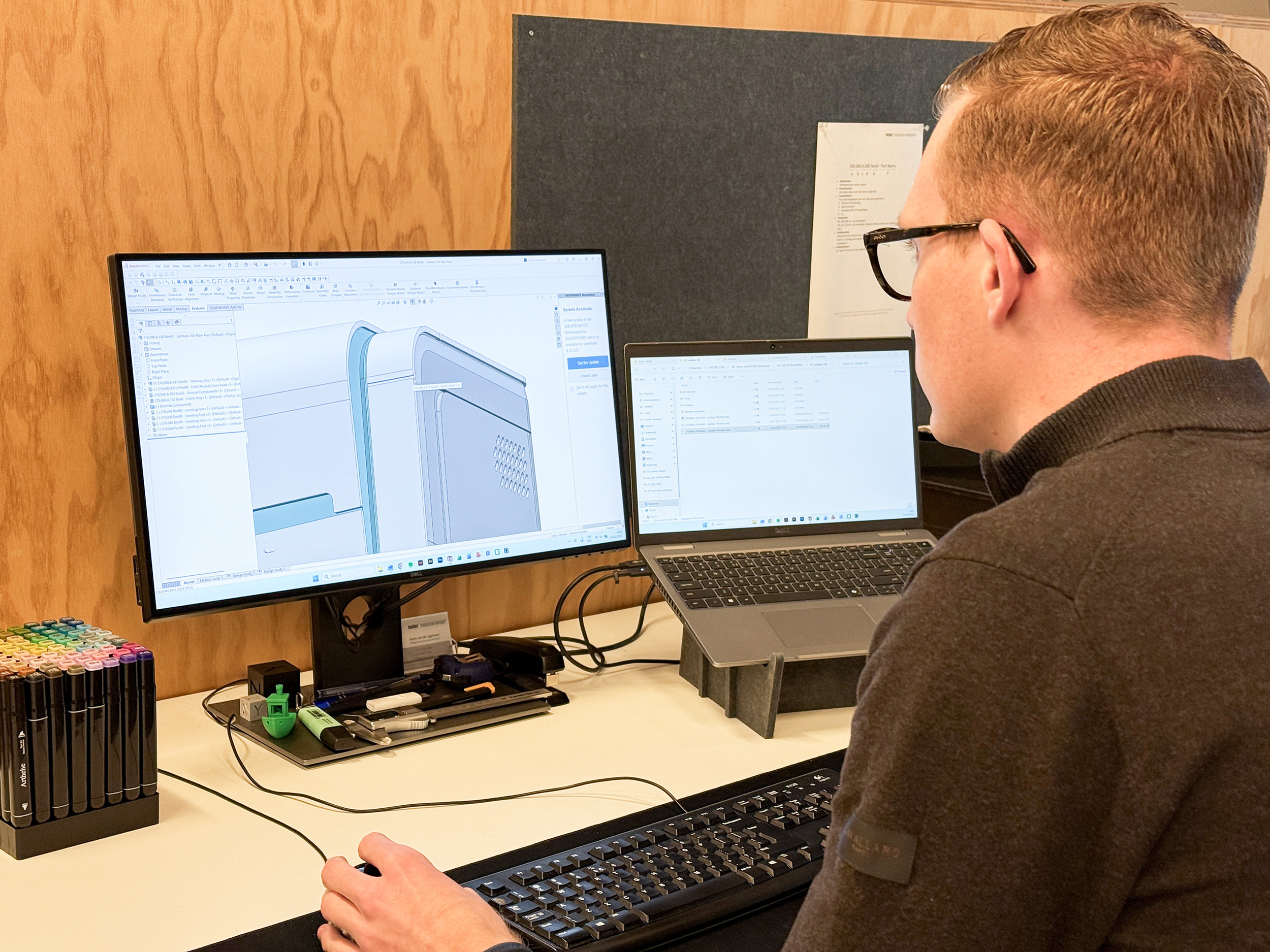

3. Engineering & technical development

Once the concept design has been determined, we translate it into a technically feasible product. Using 3D CAD software, we develop the design in full detail, considering aspects as fastening methods, material and texture selection and tolerances.

To work efficiently, we incorporate Design for Manufacturing (DFM) early in this phase. The design is optimized for serial production and efficient assembly. By collaborating closely with suppliers and manufacturers, we ensure an (efficiently) feasible product.

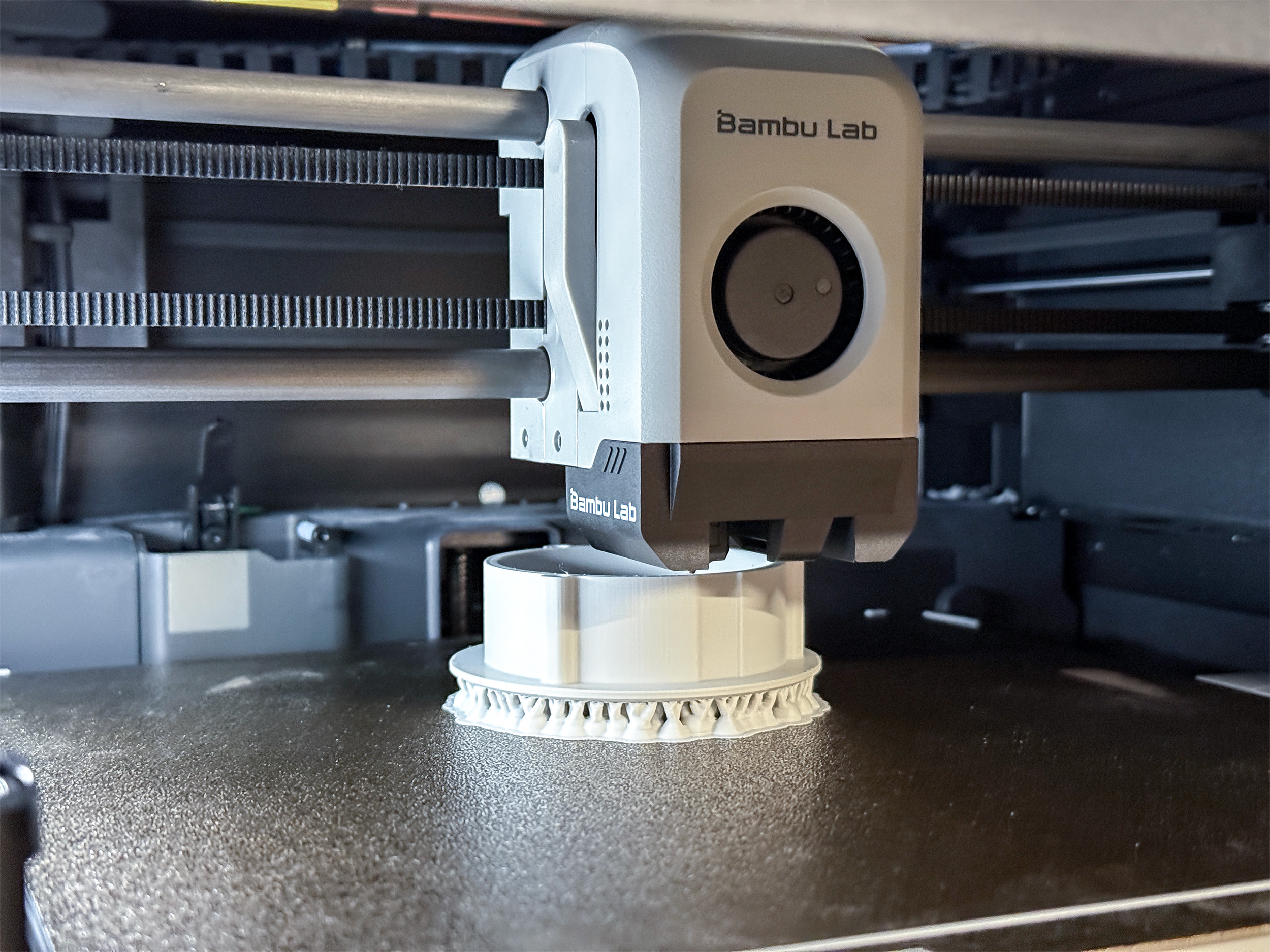

4. Prototyping & validation

Prototyping plays a crucial role in the entire design process. By creating physical models and functional prototypes, we can test, evaluate and refine the product. This provides valuable insights into ergonomics, functionality, and user experience.

In many cases, it is desirable to prototype the entire product, so it can be validated before starting production. This could be a presentation model for a trade show or a technically functioning prototype for mechanical testing.

5. Production preparation & support

Once the design has been validated, the production process can be started. We deliver production-ready files and technical drawings. Some clients take it from there with their own preferred suppliers, while others ask us to manage the process. Over the years, we have built a reliable network of manufacturers in the Netherlands, Europe, and Asia. For this purpose, we established a dedicated branch: Helder Products.

Even during tooling and production, we remain involved to ensure quality and implement any necessary optimizations. This way, we make sure the final product is not only well designed but also meets all requirements.

How can we support you?

Do you need support in the design process? We are ready to assist you at every stage. And even if your product is nearly finished but you’re looking for a reliable partner for serial production, we’re happy to help.