Medical Design

Where form, function, and safety meet

In the world of medical innovation, product design plays a crucial role. It forms the bridge between technology, ergonomics, and aesthetics. At Helder Industrial Design, we believe that a well-designed medical product should not only function effectively, but also convey trust and a sense of safety to both healthcare professionals and patients.

Medical design is distinct from traditional product development because of the complex demands these products must meet. It’s not just about creating something that looks good, but about ensuring safety, hygiene, and ease of use.

What is medical design, really?

In simple terms, medical design involves creating medical devices and tools with a strong focus on user needs, safety, and functionality. It is a careful process where every aspect of use, performance, and production is considered.

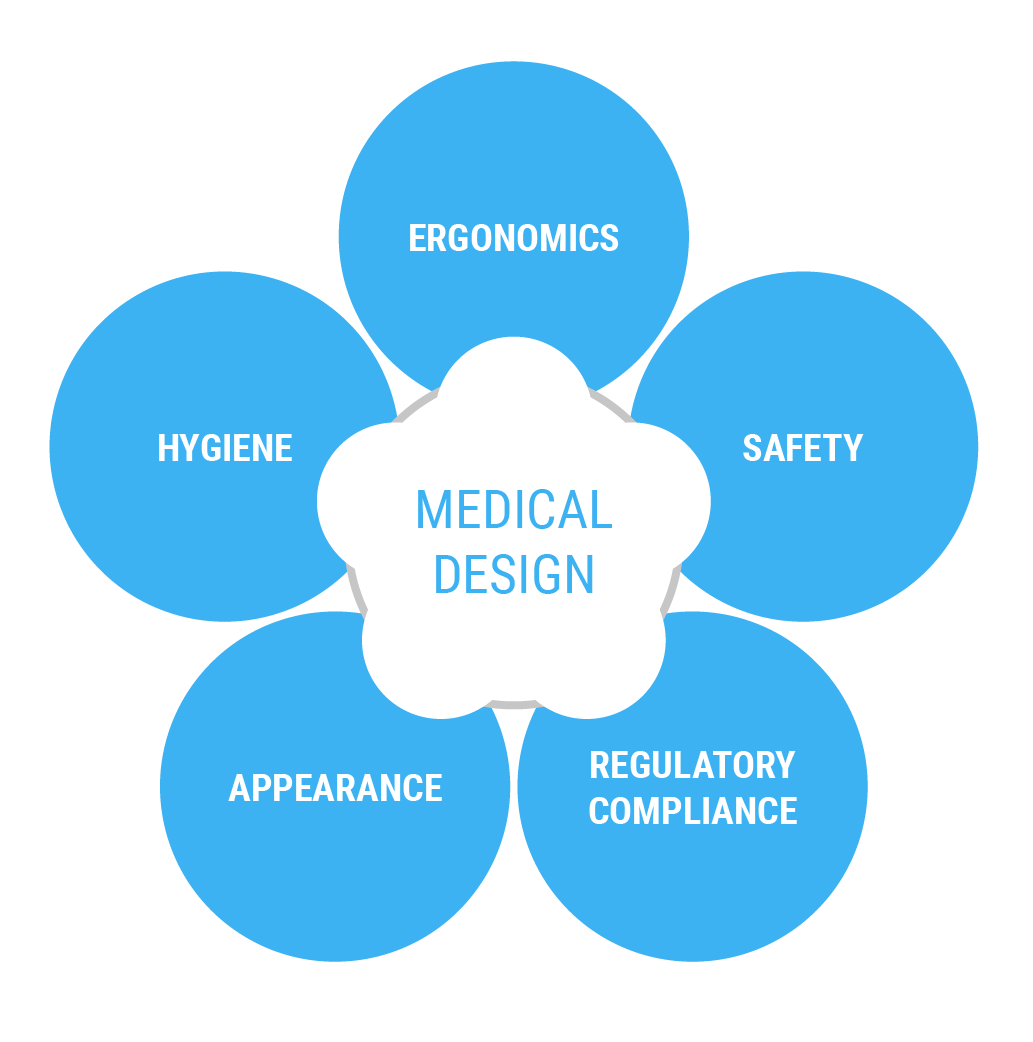

Some of the key elements of medical design include:

- Ergonomics: Products must be easy and comfortable to use for both healthcare professionals and patients.

- Hygiene: Materials and shapes need to be easy to clean to prevent infection and contamination.

- Safety: Clear instructions and intuitive visual or tactile signals help ensure the product is used correctly.

- Appearance: A friendly and intuitive design helps build trust with users.

- Regulatory compliance: Products must meet international standards and legal requirements.

The role of industrial design in medical innovation

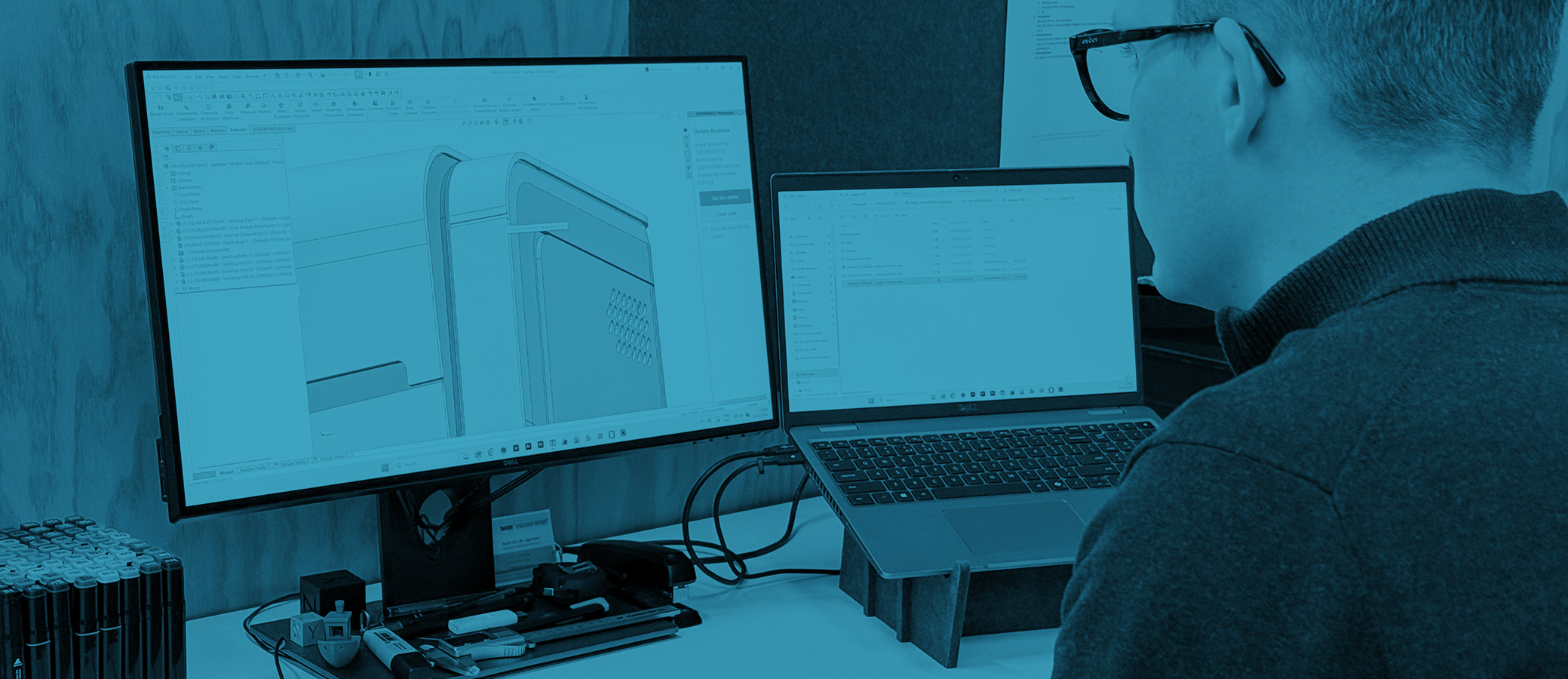

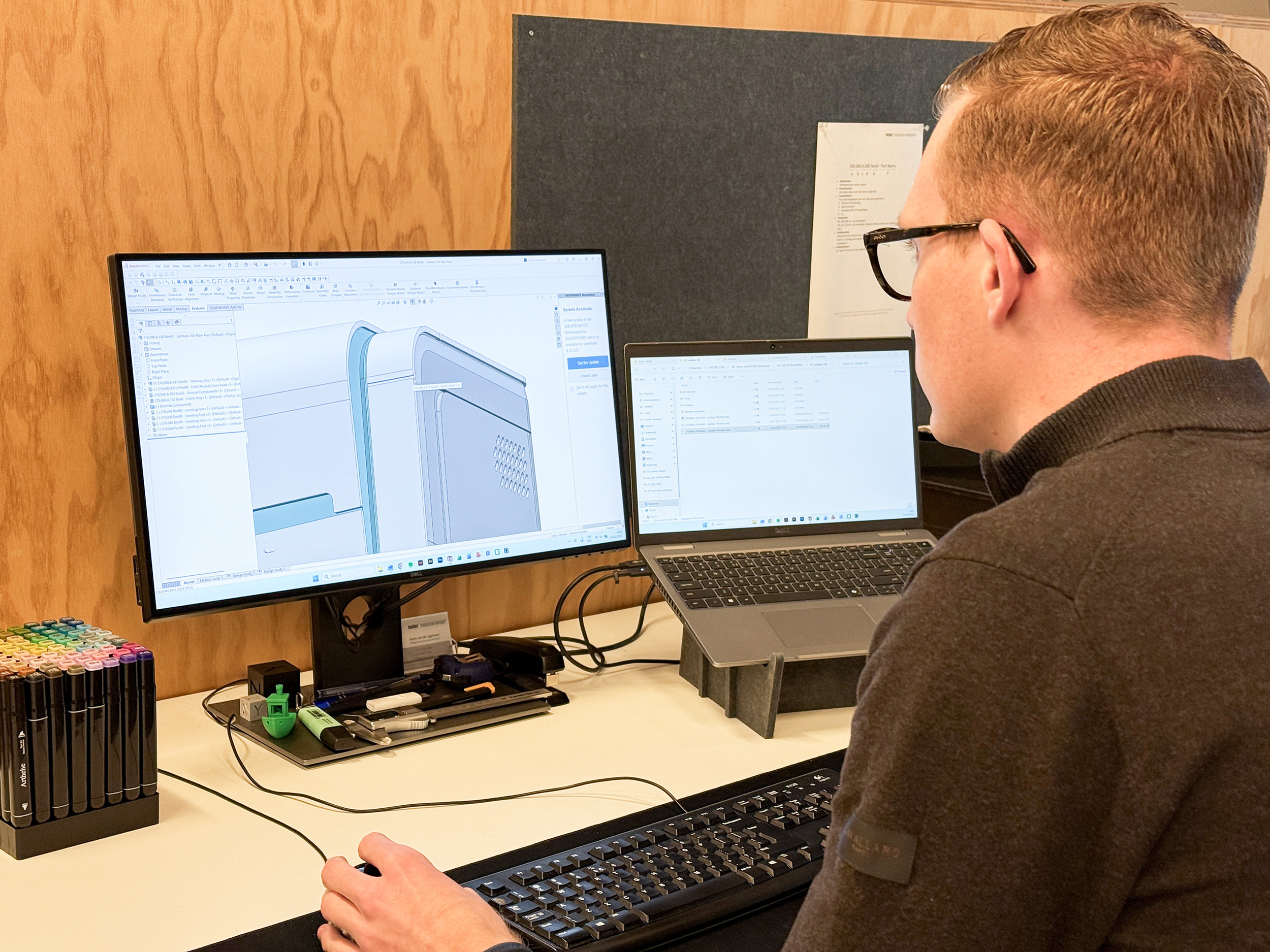

When developing a new medical application, it is essential to bring together technical performance and user experience. The product must work flawlessly, and users must be able to operate it safely and intuitively. Design also plays a major role in product acceptance. If a product looks reliable and user-friendly, it gives people confidence, which is key to its success. Industrial designers focus on exactly these factors and play an important part in turning innovation into reality.

Case study: Vitestro

One example where all these aspects came into play is Vitestro’s blood collection robot. This machine allows patients to draw their own blood under the supervision of a healthcare professional. Helder was involved in designing and engineering a suitable housing for the product.

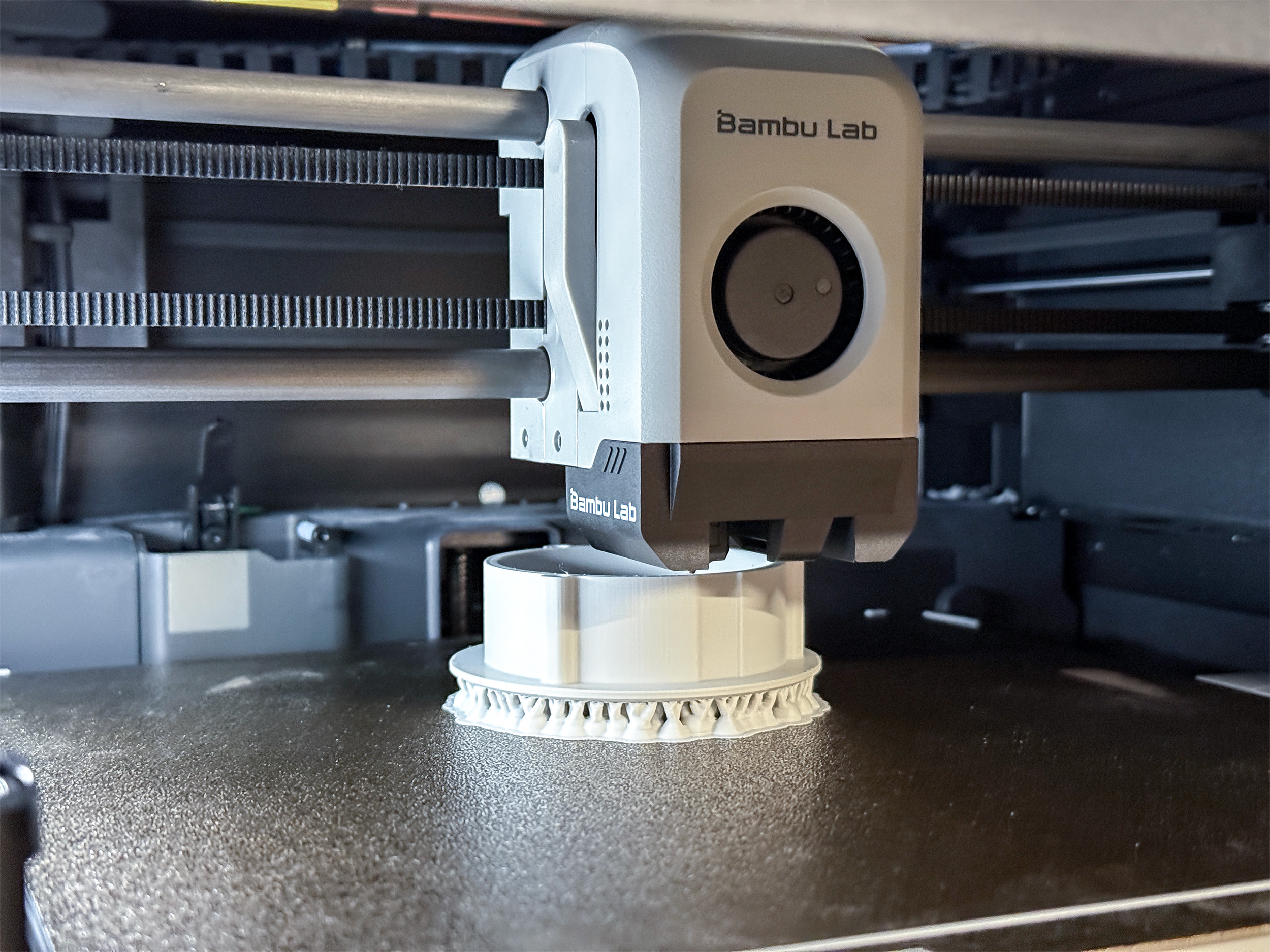

By using full-size mock-ups, we were able to study the actions of both patients and medical staff. Based on these insights, we created a housing that meets requirements for ergonomics, safety, and cleanability. The product also has a friendly and reliable appearance, which supports its acceptance in medical environments.

You can find more information and visuals from this project on the project page.

From idea to certified product

Developing a medical product is a structured and highly detailed process. Strict requirements and international standards must be followed, and the entire process needs to be traceable. Risk analysis is a critical step to ensure safe use. At Helder, we support our clients every step of the way, combining a strong attention to detail with expertise in materials and processes. We also guide clients through the path to CE certification, so that their product is not only innovative, but also safe and compliant.

Beyond design: Full-scope support in medical product development

While this article highlights the importance of product design, our involvement often extends well beyond that stage. Through Helder Products, we assist clients with the sourcing and production of molds, parts, and components, collaborating with our trusted network of certified manufacturing partners. This ensures that medical products are not only thoughtfully designed, but also ready for reliable and scalable production. In an upcoming blog post, we’ll take a closer look at these capabilities and how they contribute to successful medical innovations.

Need support?

Working on a medical innovation? We are here to help. Reach out to us if you are looking for a partner who can think along with you in every phase of development and help bring a high-quality end result to life.