Ecolite® Pallets

In 2015, the inventor Tristan Melland approached Helder-id with the request to help him develop his idea for a transport pallet made of sheet metal. Helder-id subsequently developed a first concept in close consultation with Gridesic. Working closely with the exclusive global licensee of the Gridesic technology, Ecolite Pallets Limited, Helder-id helped refine and improve the initial concept until a viable manufacturing prototype was designed.

The Metalton pallet is suitable for a variety of logistical applications in multiple industries including:

- Consignments with high sanitation requirements.

– E.g. pharmaceuticals, fresh and perishable products. - High-value shipments.

– E.g. sensitive electronics, automotive parts. - Transport and storage in aggressive environments

– E.g. chemicals, toxic products. - Cold-chain logistics.

Metalton is a registered trademark of Gridesic Holdings Limited. Ecolite Pallets Limited is the exclusive global licensee for the design development, manufacture, distribution, and marketing of pallets using the Gridesic patents and IP.

Industry

Professional

Logistics

Services

Concept development

Engineering for production

Patented spaceframe design

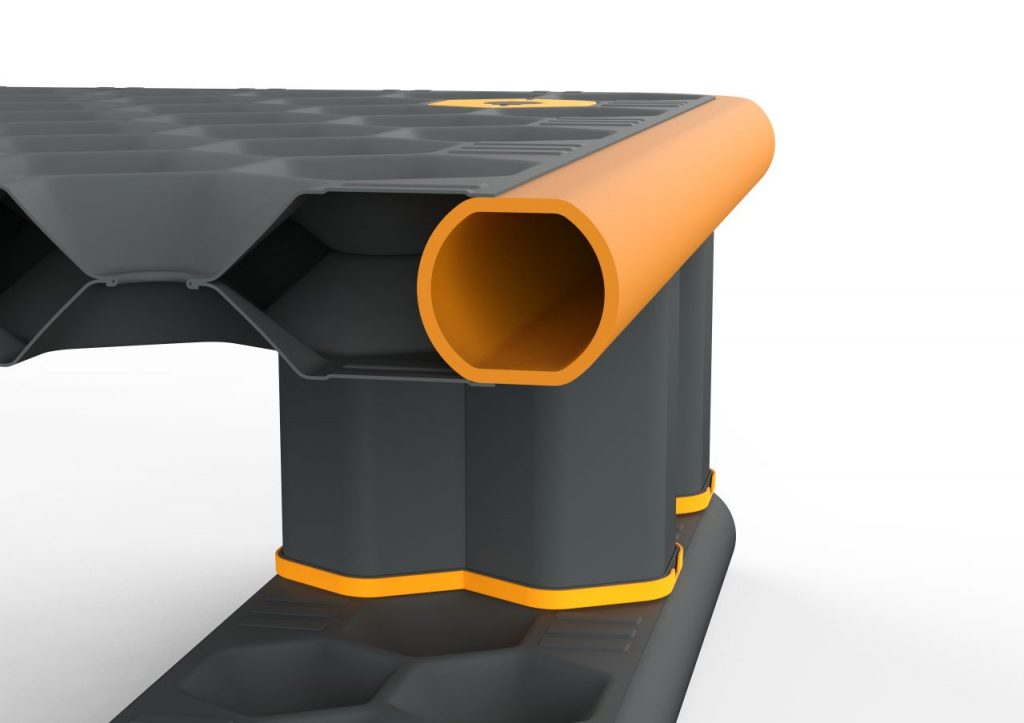

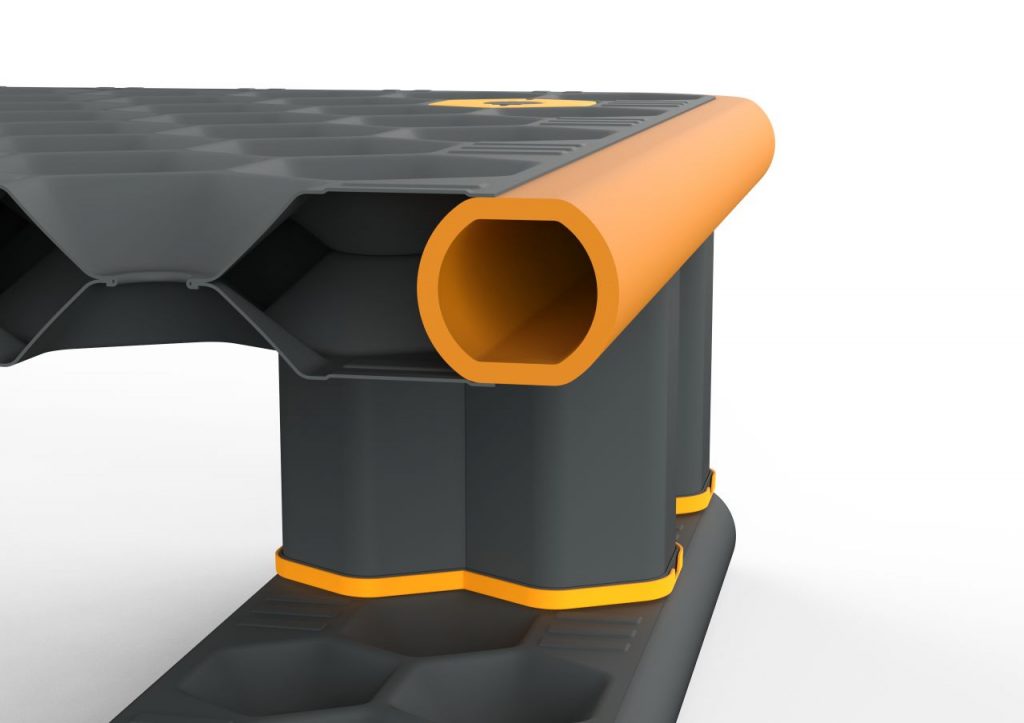

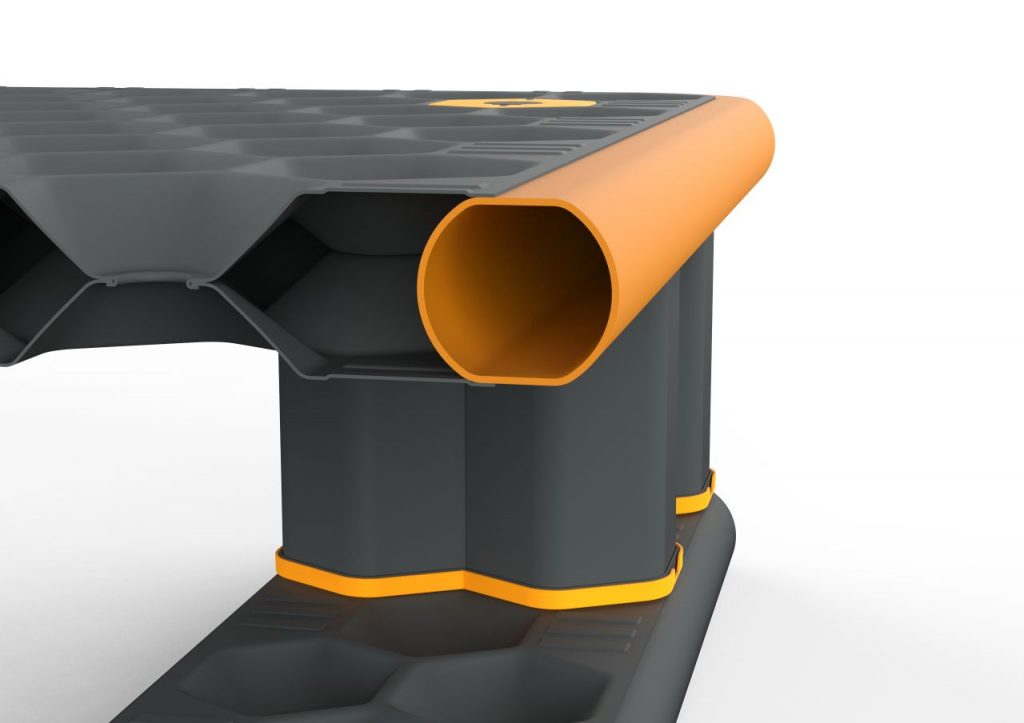

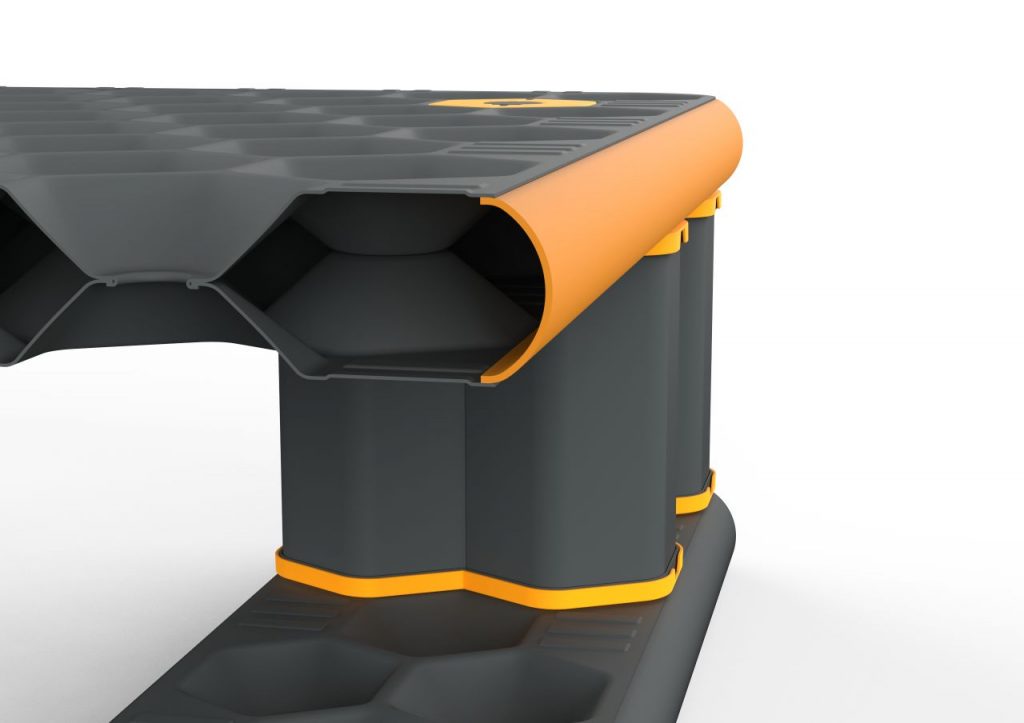

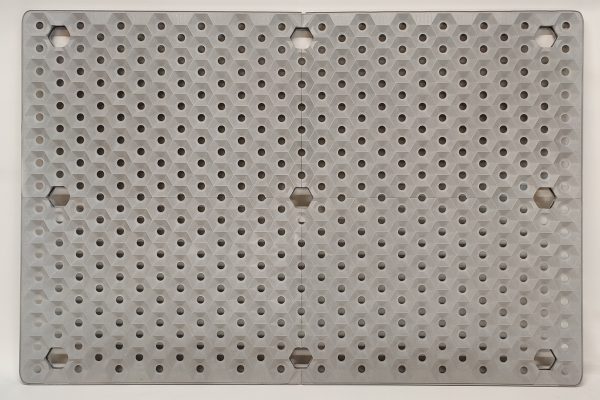

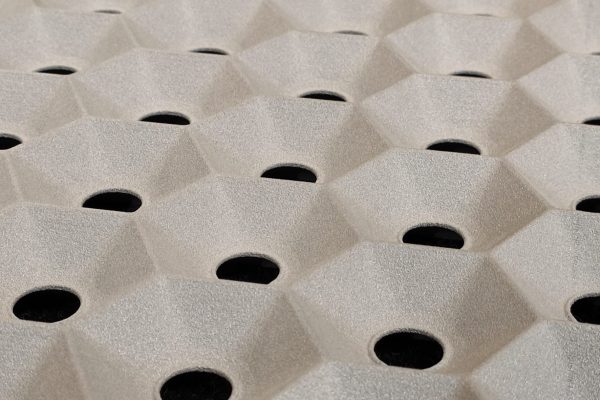

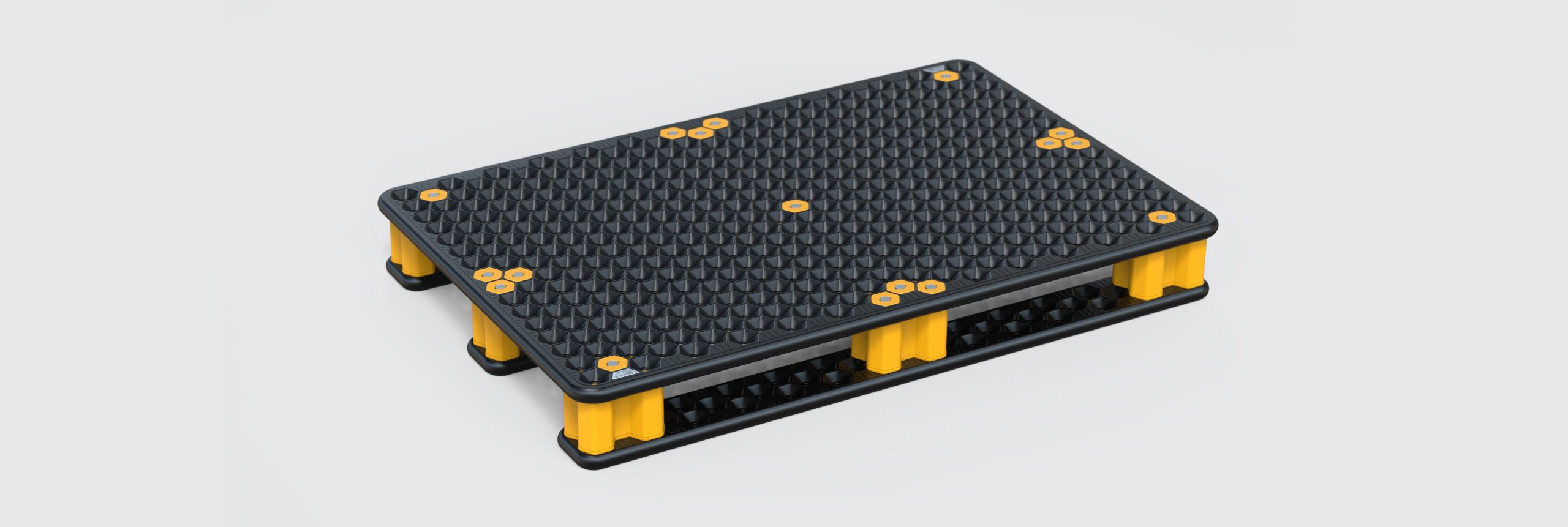

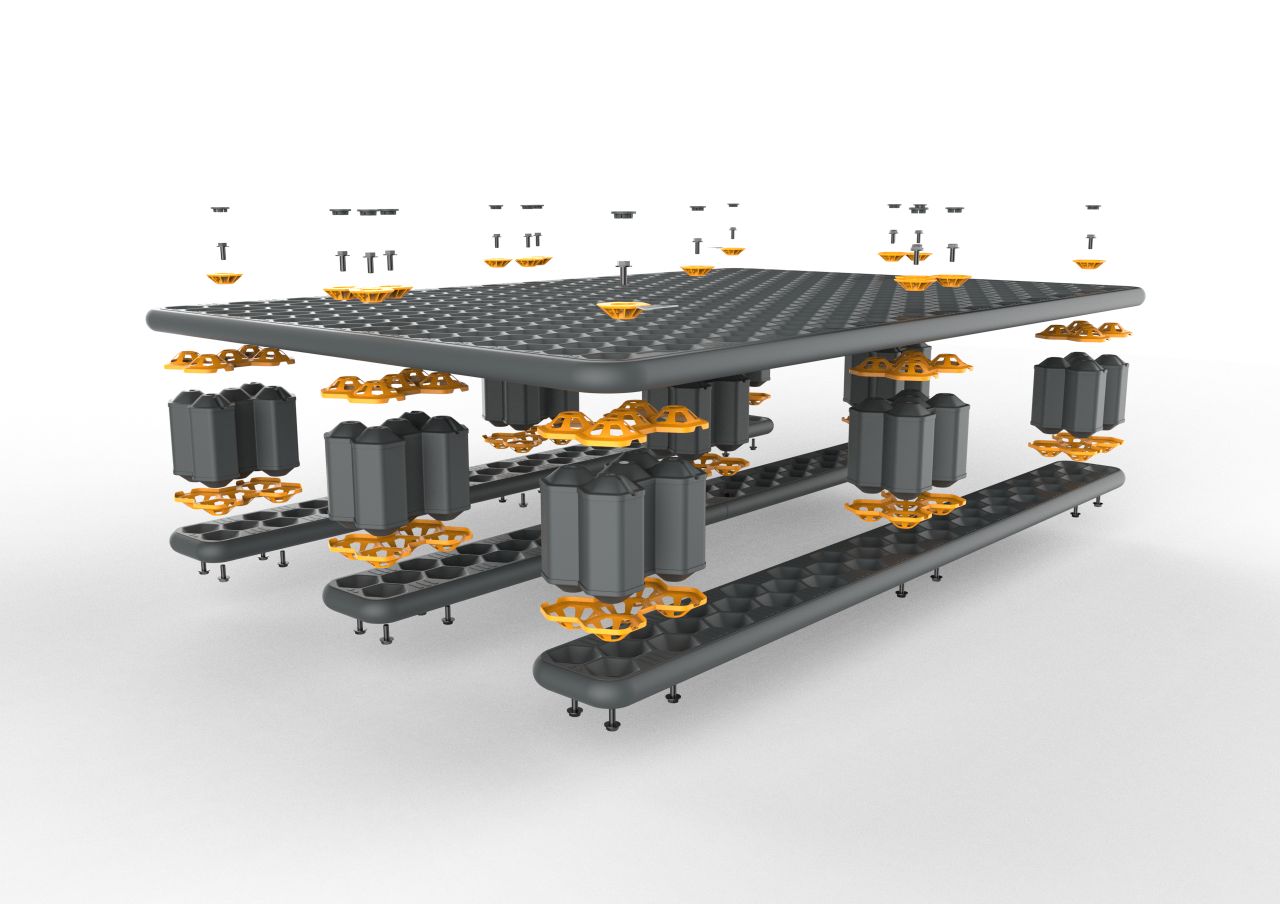

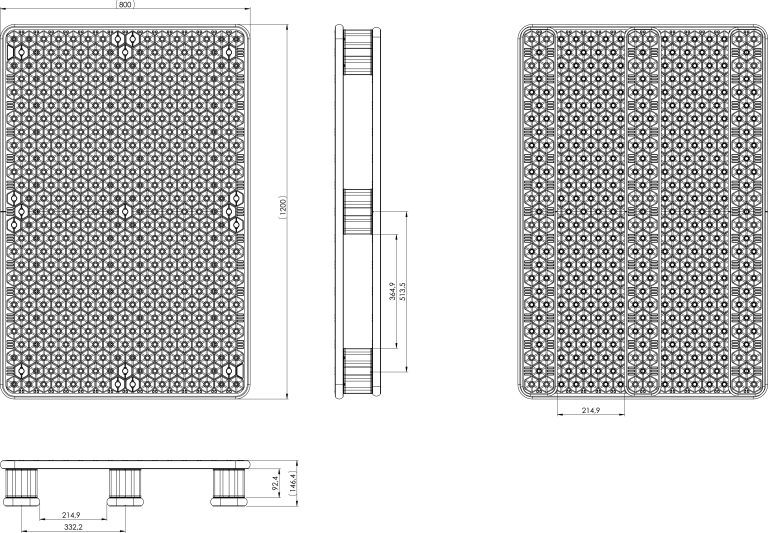

The concept is based on a spaceframe design in which two press formed metal sheets are mounted on top of each other forming an array of pods that act as a three-dimensional truss construction, providing a very light and rigid structure with an extremely high load-bearing capacity.

The patented spaceframe pod design allows loads to be dissipated between the top and bottom panels via the folded edges of the sheet metal and the crimped connections in the center of each pod. The robotic laser welded sides of the pallet are equipped with steel profiles to absorb impact and protect the edges from forklift damage. This creates a closed box construction where no liquid can penetrate or remain behind, making the pallets very suitable for sanitary and hygienic applications.

An environmentally conscious pallet

Each year, billions of shipping pallets are used all around the world. The vast majority of these (about 95%) are made of wood. And many are used only for one-way shipping. The Metalton pallet is made from steel, one of the most economic, commonly available materials, and is infinitely recyclable. The lightweight Metalton pallets are robust and durable. Helder-id designed a modular assembly in which the legs are bolted to the top panel and skids, allowing easy replacement of damaged parts. Altogether, it saves trees and offers low CO2 footprint in manufacture and use.

Iterative design

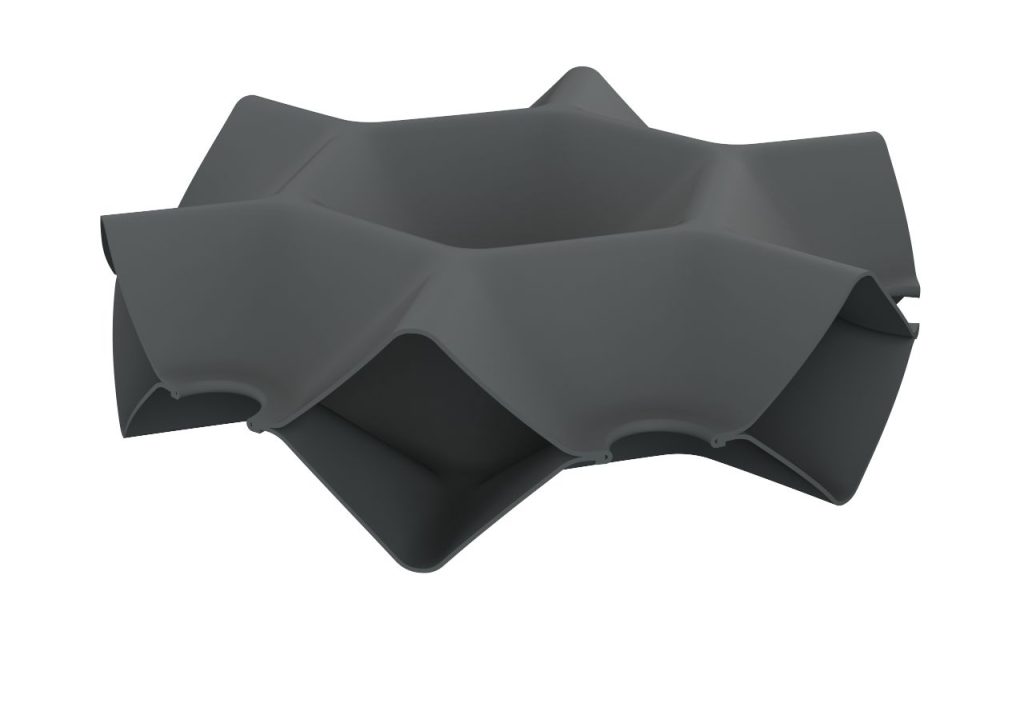

The geometric concept of the pallets touches the edges of what is possible in sheet metal. Therefore, the development of the pallets involved a continuous cyclic process of CAD-modelling, analyzing, prototyping, testing, and refining of the design. During the entire process, there was intensive collaboration with both the client, the external specialists in the field of final element analysis (FEM) and the ultimate toolmaker and manufacturer.

Prototyping challenges

The sheet metal fabrication techniques needed for the realization of the pallet are quite common in the automotive industry but require huge investments in pressing tools. Also, it’s very difficult to make representative prototypes without that tooling. Although various 3D printed models were made, both of details and the entire pallet, it was very challenging to emulate the characteristics of the final life size product. This made it necessary to repeatedly analyze the design using CAD simulation and FEM validation techniques.