KlikAanKlikUit Smart Bridge

KlikAanKlikUit (or Trust Switch-in) is a brand name of the Dutch company Trust International, manufacturer of computer accessories and other digital lifestyle products. The KlikAanKlikUit product line features a wide range of home-automation products, including smart switches, plugs, remote controls, smoke detectors and other home security products. The original KlikAanKlikUit products were radio-connected at 433 mHz, while the later products increasingly made use of Zigbee and Wifi.

To connect the different product lines, a special gateway was developed in close collaboration with the electronics developers of Sensorfy. This Smart Bridge internet gateway also allows the user to control the products with an Android or iOS app on a smartphone. Helder-id was asked to design and develop a suitable enclosure with a fresh and modern look.

Industry

Consumer products

Home automation

Connectivity

Services

Product design

DFM

Sustainability design

Process & Tooling management

Realization

Modest but noteworthy design

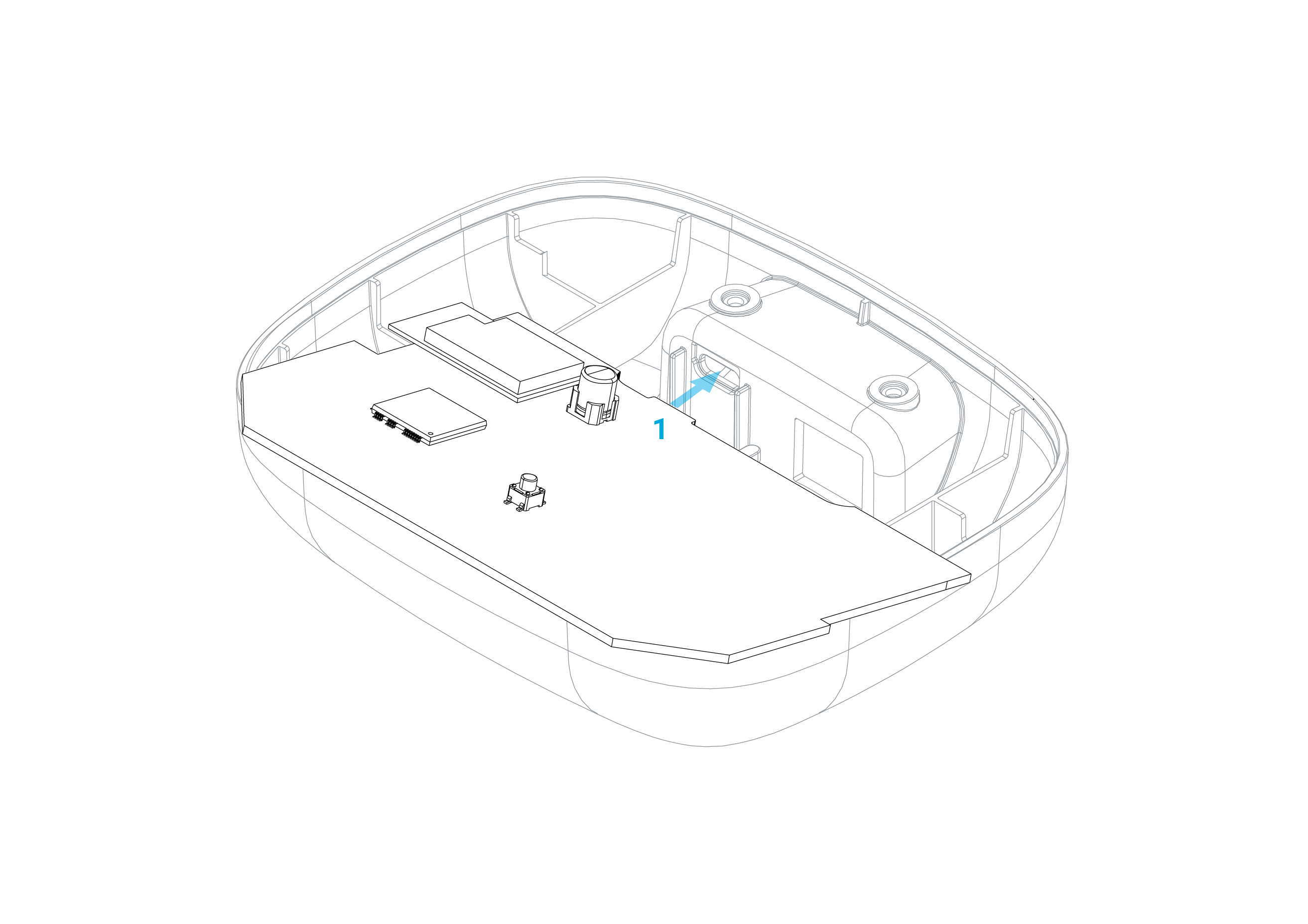

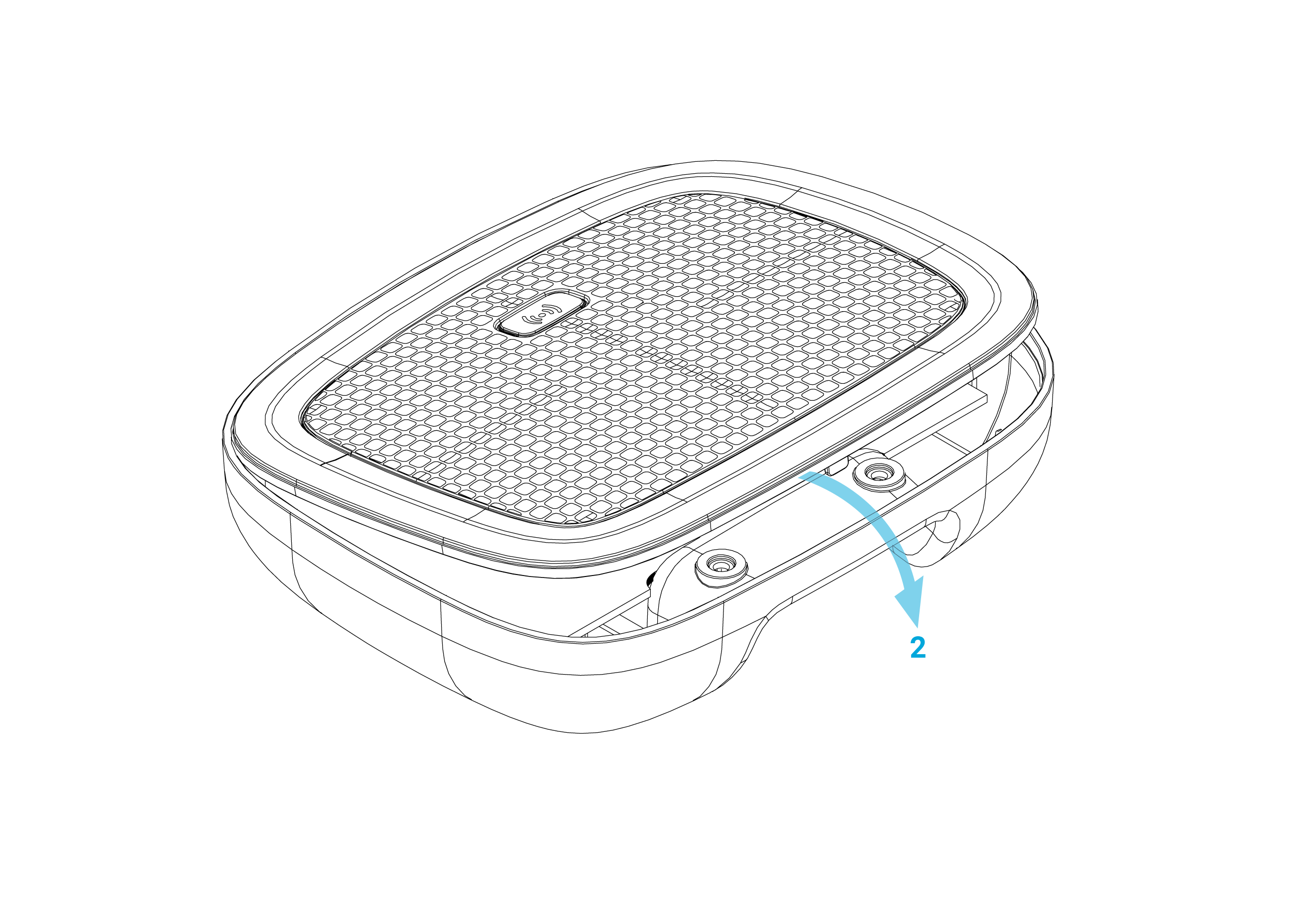

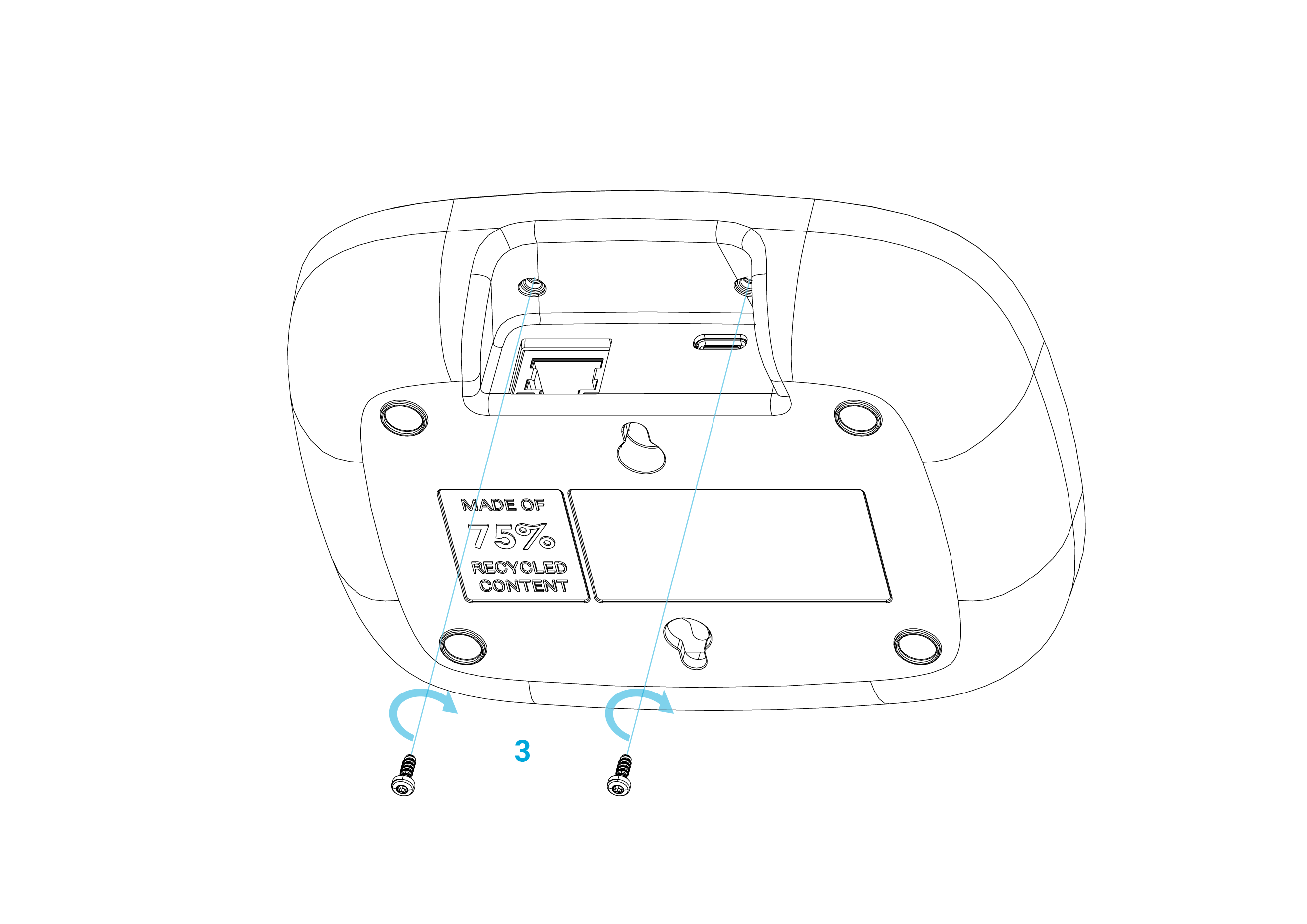

Although the gateway is expected to be often installed in the meter box, Trust wanted an enclosure that people would be proud to place on a table or sideboard. The approach was a contemporary design, not too pronounced, but with stylish details and a neutral use of colors. All sockets for external cables are neatly placed in a recess on the bottom, so that unsightly connectors are hidden from view. After consideration, it turned out that only one control was required in the form of a backlit button. Different statuses can be indicated by using a single multi-color LED.

Design for assembly

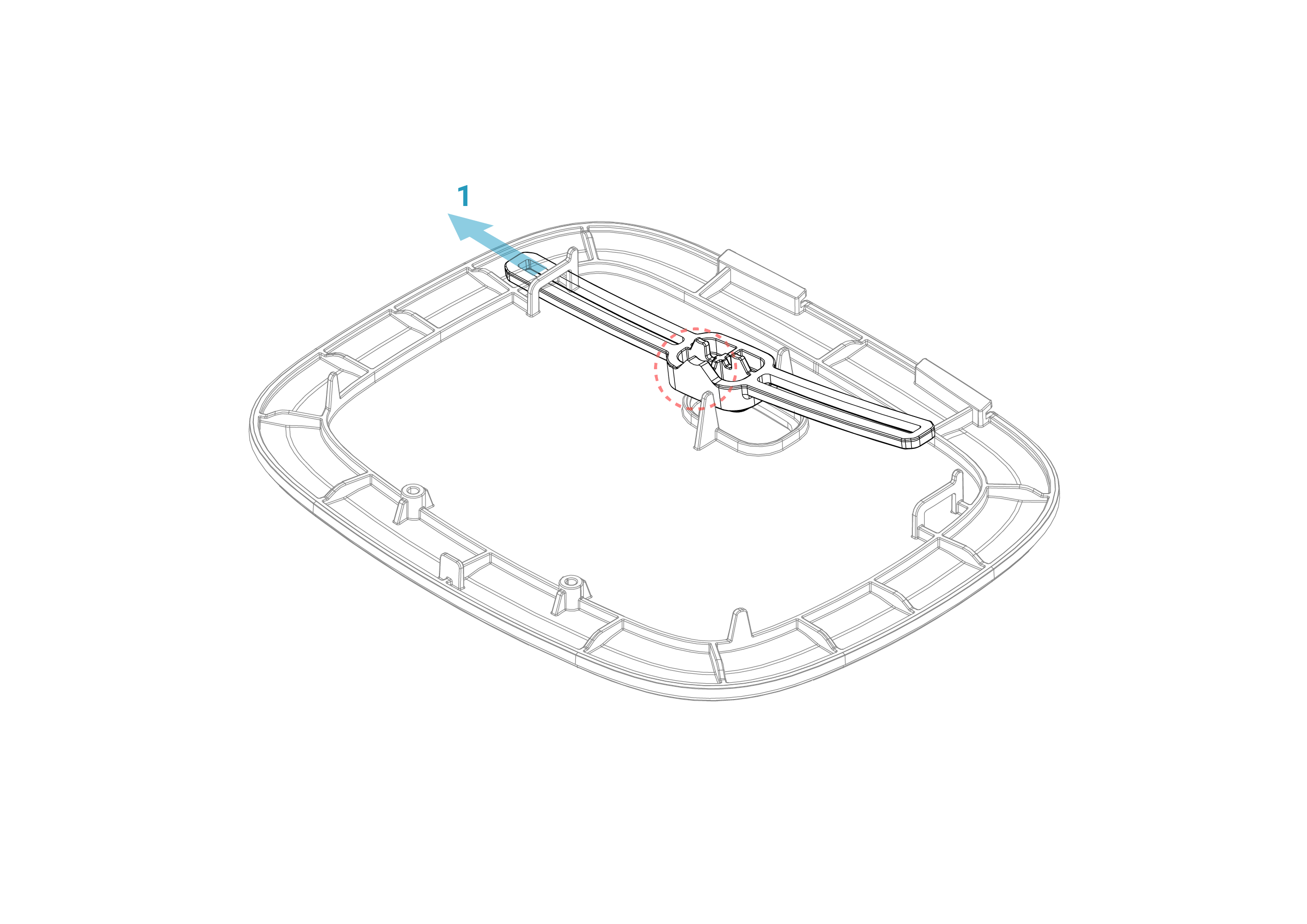

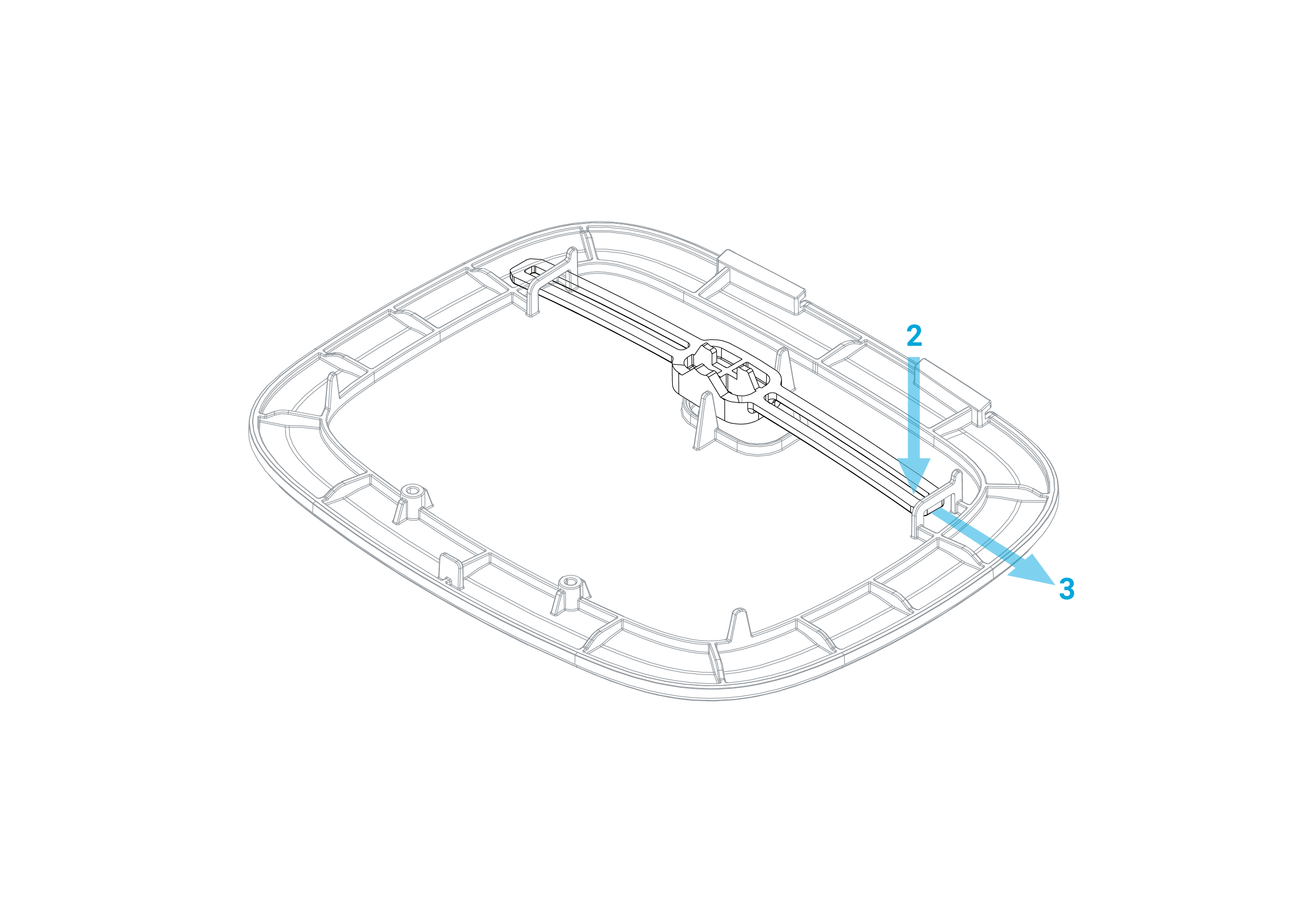

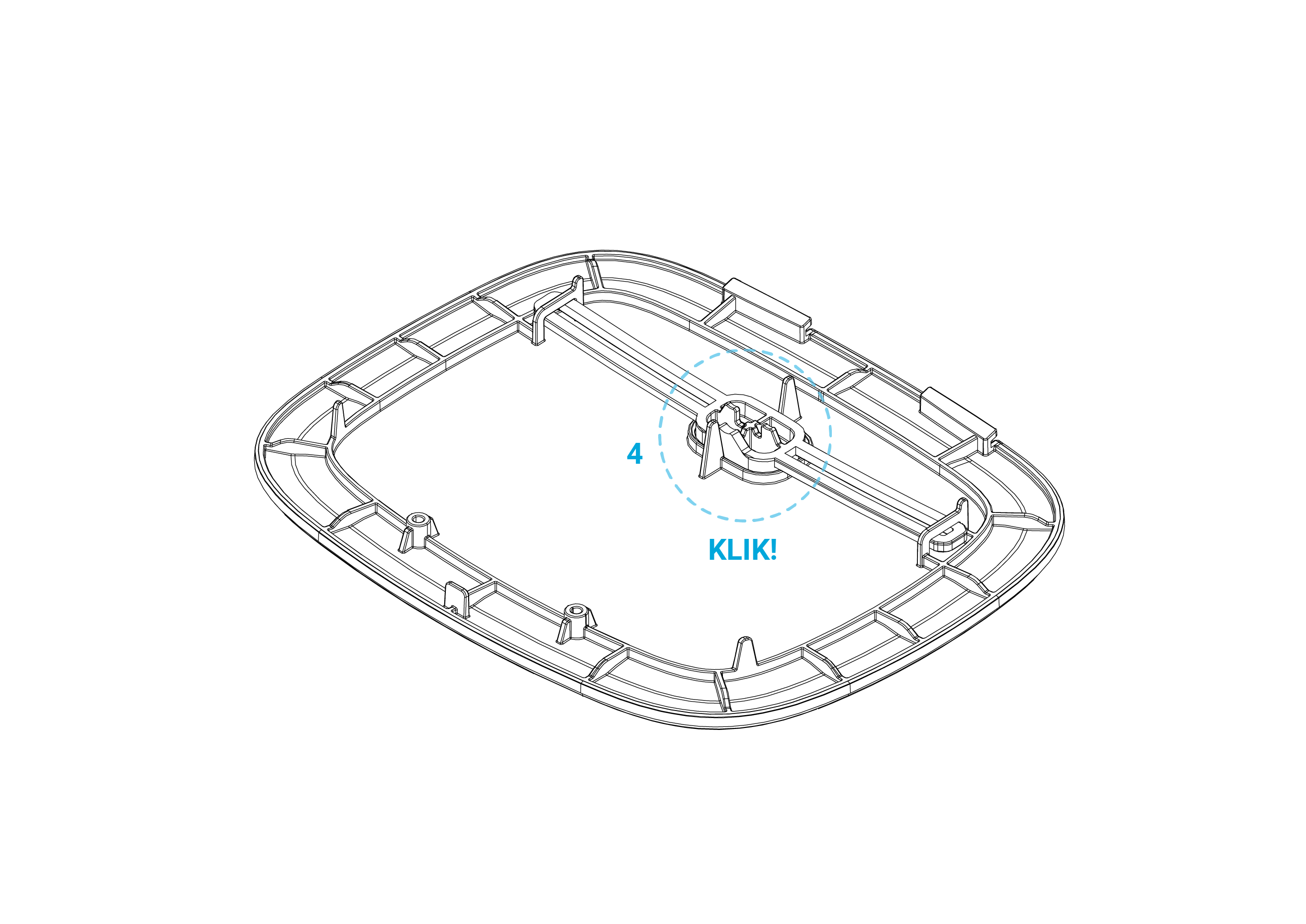

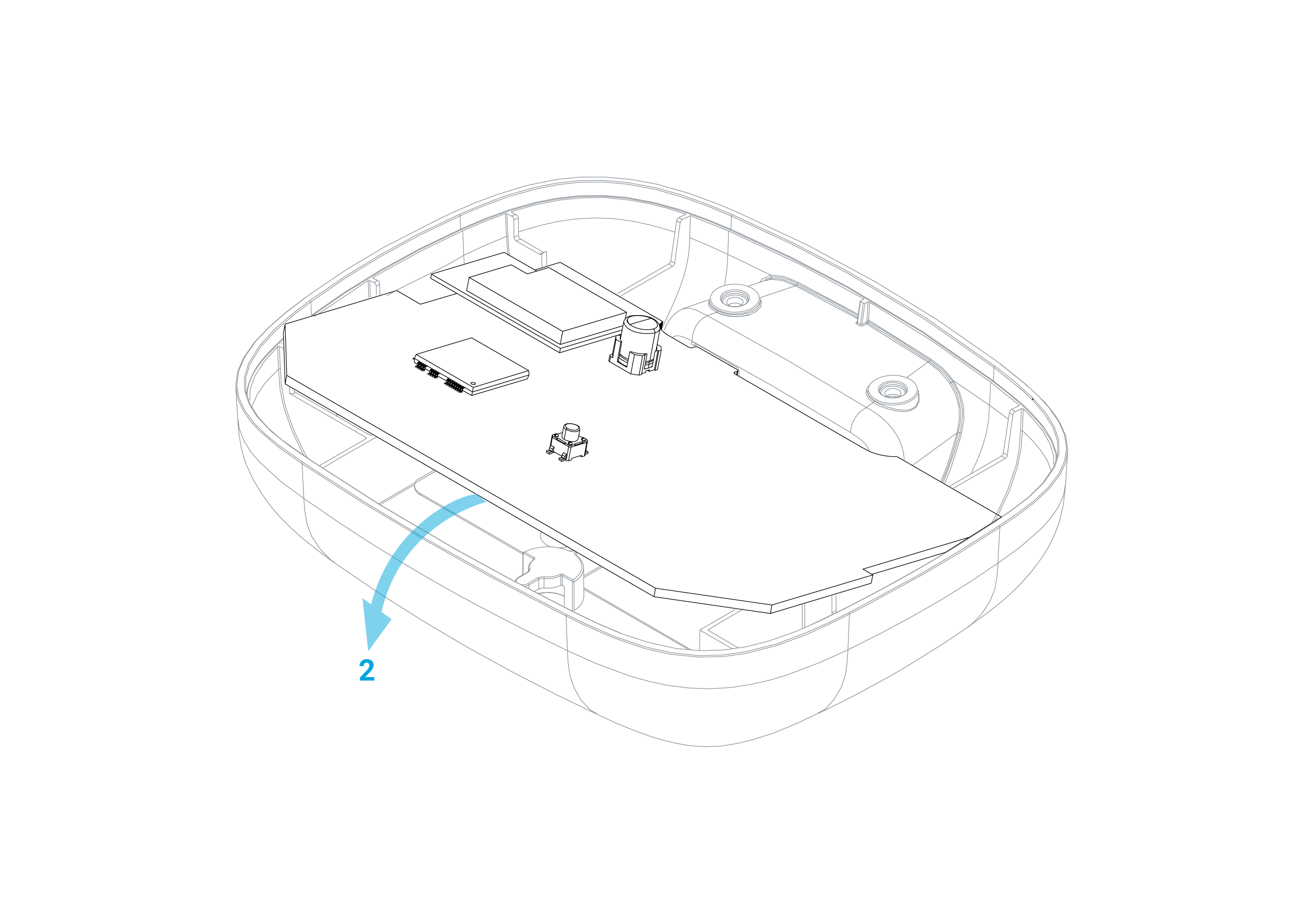

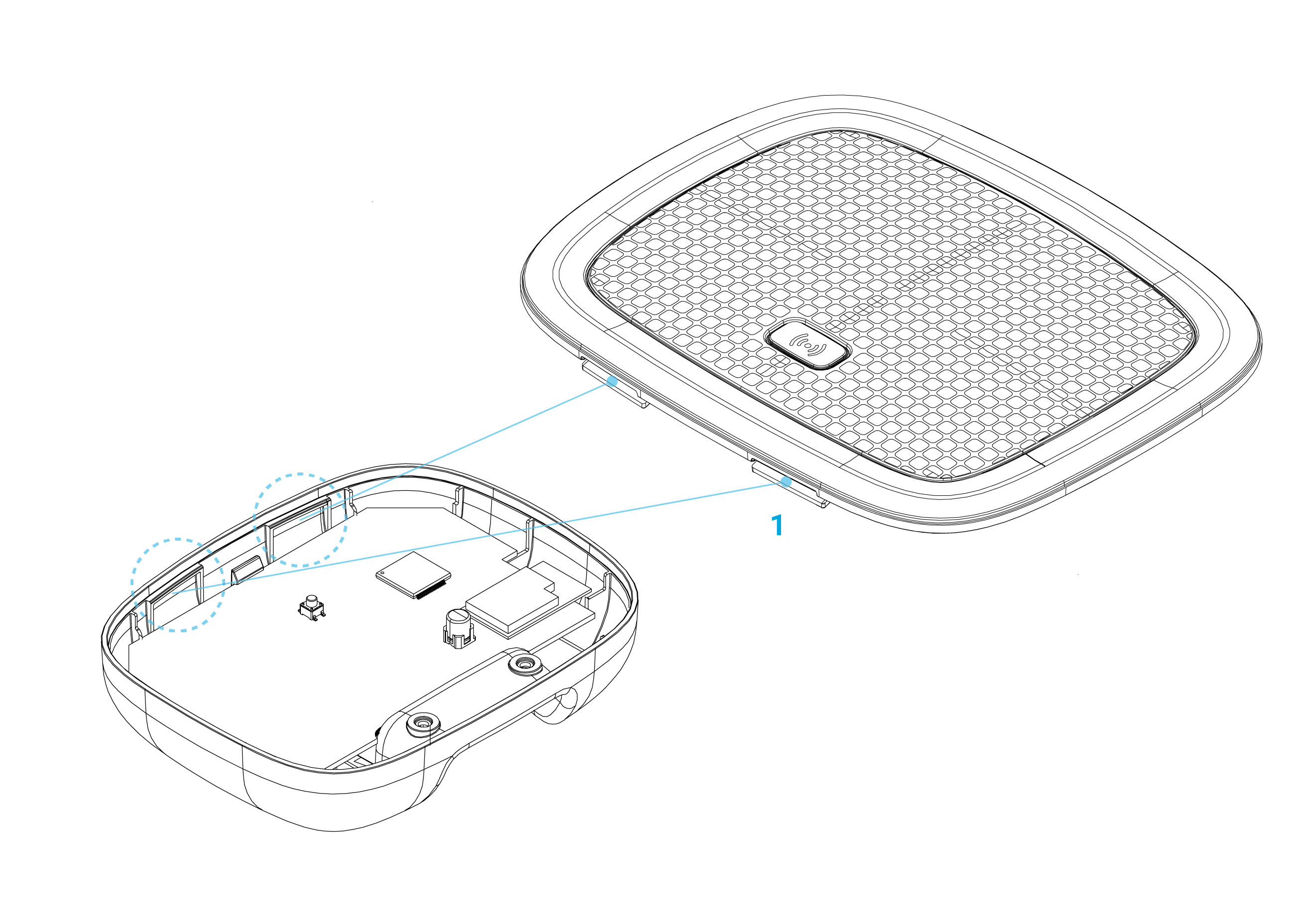

Starting point was to develop and produce the gateway in the Netherlands/Europe. Thus, efficient ways of assembly were therefore of great importance. In close consultation with the Sensorfy team, we developed a simple method to click the PCB into the bottom shell of the housing, which is then secured together with the top part using just two screws (which also scored good in the EU repairability index).

Sustainable design

At the start of the project, Trust asked about the possibilities of making the enclosure more sustainable, for example by using recycled materials. The Helder-id team was pleasantly surprised by this question, because this is a topic that we have a lot of knowledge about and are also happy to promote. The initial goal was to use 50% post-consumer recycled materials, but after some research we found a good source for a PC/ABS that meets all mechanical requirements for electronic consumer products, allowing us to achieve 100% recycled content. It is extracted from e-waste materials, so maybe your old printer or monitor enclosure is now part of this new gateway enclosure! The only drawback was that this material is only available in dark shades of gray or black, but in the end, this turned out to match the desired product appearance very well. In addition to the use of materials, we also considered the repairability index and the design-for-disassembly aspects in relation to the product’s end of life.

Efficient packaging

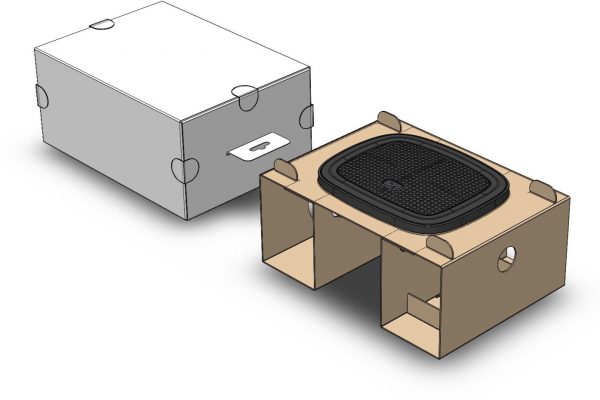

In addition to the use of materials in the device enclosure, it was also a challenge for Trust to create a packaging as sustainable as possible. Also here, the idea was to use recycled paper and cardboard, but still creating the best possible ‘unboxing experience’. Helder-id designed a smart foldable tray for this, using a minimal amount of material, but in which the product plus all the extras are neatly stored.

Production taken care of

The tooling for the plastic components was taken care of by sister company Helder Products. The idea was to have a first series of plastic parts made at the toolmaker/injection molder in China, after which the molds would be shipped to the Netherlands. The problem was that there was no certified source of 100% recycled PC/ABS available on site. Because it would be strange from a sustainability point of view to ship the raw material to China, we had to settle for a feedstock with less cycled content. That is why the first products state: ‘produced from 75% recycled content’, but after arrival in the Netherlands the insert in the mold was changed with the indication of ‘100%’.